Floor Type Boring and Milling Machine

CBM-135P/CBM-135QF/CBM-150QF

High Productivity

![]() Spindle continuously monitored to provide most efficient cutting conditions.

Spindle continuously monitored to provide most efficient cutting conditions.

![]() Each axis is independently controlled to provide maximum feed as required.

Each axis is independently controlled to provide maximum feed as required.

Powerful Spindle

![]() The specially designed spindle outer ring cooling system maintains constant bearing accuracy under normal operating conditions. This gear type auto-shift design and grease lubrication system also provides superior machine performance and reliability.

The specially designed spindle outer ring cooling system maintains constant bearing accuracy under normal operating conditions. This gear type auto-shift design and grease lubrication system also provides superior machine performance and reliability.

![]() The spindle and boring bar are made of SACM645 alloy. The spindle has been Nitrided to HRC62~68. This hardness maintains spindle form and insures high reliability. This increased rigidity increases the overall machine capability.

The spindle and boring bar are made of SACM645 alloy. The spindle has been Nitrided to HRC62~68. This hardness maintains spindle form and insures high reliability. This increased rigidity increases the overall machine capability.

![]() We use the very highest quality spindle bearings from SKF and NSK. These high quality bearings insure machine consistency and a longer machine life.

We use the very highest quality spindle bearings from SKF and NSK. These high quality bearings insure machine consistency and a longer machine life.

High Rigidity

![]() For the vertical travel of headstock, the spindle travel, high quality ball screws are used. All sliding surfaces are automatically lubricated.

For the vertical travel of headstock, the spindle travel, high quality ball screws are used. All sliding surfaces are automatically lubricated.

![]() The clamps for headstock vertical travel is hydraulic counterweight.

The clamps for headstock vertical travel is hydraulic counterweight.

![]() The major structural members are box-shaped with best possible arrangements of ribs with a large cross-sectional area, providing highest rigidity long-term accuracy and precision.

The major structural members are box-shaped with best possible arrangements of ribs with a large cross-sectional area, providing highest rigidity long-term accuracy and precision.

High Precise Slide ways

![]() The column and bed slide ways are hardened and ground. The mating surfaces of the moving units are coated with a special fluorine resin, and forced-lubricated so that the system for slide ways offers minimum friction resulting in high precision which will be maintained over a long period of time, this ensures a very smooth feed stroke even at low speeds without stick/slip.

The column and bed slide ways are hardened and ground. The mating surfaces of the moving units are coated with a special fluorine resin, and forced-lubricated so that the system for slide ways offers minimum friction resulting in high precision which will be maintained over a long period of time, this ensures a very smooth feed stroke even at low speeds without stick/slip.

Easy Operation

![]() The switches on the pendant control box have the most efficient layouts for working respectively. This ensures improved operating efficiency.

The switches on the pendant control box have the most efficient layouts for working respectively. This ensures improved operating efficiency.

![]() The contents of programs and the current positions are displayed on the CRT display. This enables to make preparation and checking of the programs easily.

The contents of programs and the current positions are displayed on the CRT display. This enables to make preparation and checking of the programs easily.

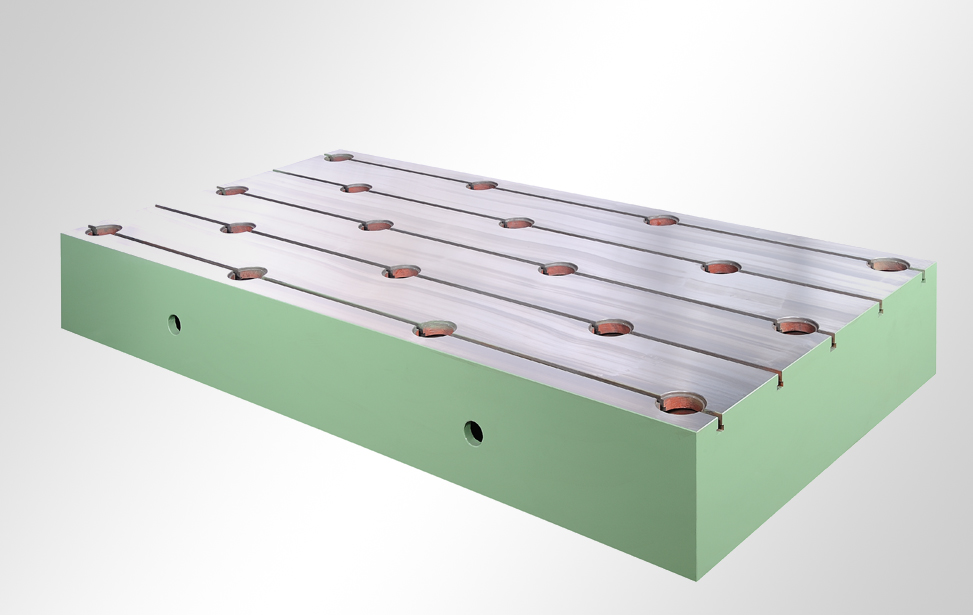

Rotary Table

![]() This special combination of highly rigid box ways, ball screws, and worm gear automatic lubrication system provides a highly satisfying compact rotary table design. With the Heidenhain angle encoder installed in the rotary table center shaft, combined with our specially designed hydraulic clamping system and positioning index pins, our machines can achieve any cutting angle. Reinforced heavy cutting angles at 0°, 90°, 180°, and 270° are included features. Hence resulting in superior accuracy and cutting efficiency.

This special combination of highly rigid box ways, ball screws, and worm gear automatic lubrication system provides a highly satisfying compact rotary table design. With the Heidenhain angle encoder installed in the rotary table center shaft, combined with our specially designed hydraulic clamping system and positioning index pins, our machines can achieve any cutting angle. Reinforced heavy cutting angles at 0°, 90°, 180°, and 270° are included features. Hence resulting in superior accuracy and cutting efficiency.

| Model | Unit | CBM-135P | CBM-135QF | CBM-150QF | ||

| Spindle | Main Motor (Cont/30min) | kw | AC 37/45 | AC 37/45 | AC 45/55 | |

| Spindle Speed | rpm | 5-2000 | 5-1200 | 5-1200 | ||

| Spindle Taper | ISO-50/BT-50 | ISO-50/BT-50 | ISO-50/BT-50 | |||

| Spindle Diameter | mm | Ø135 | Ø135 | Ø150 | ||

| Spindle End Diameter | mm | Ø215 | Ø215 | Ø250 | ||

| Quill Diameter(Z2 Axis) | mm | X | Ø380 | Ø380 | ||

| Spindle Max. Torque | Nm | 2150 | 2150 | 2620 | ||

| Travel | X Axis (Column Cross Travel) | mm | 2000-6000 : Ball screw 6000-10000 : Rack |

|||

| Y Axis (Spindle Vertical Travel) | mm | 2000、2500、3000、3500 | ||||

| Z1 Axis (Spindle Travel) | mm | 700 | 700 | 900 | ||

| Z2 Axis (Quill Travel) | mm | X | 350 (*option) | 400 (*option) | ||

| Spindle Total Travel (Z1+Z2) | mm | 700 | 1050 | 1300 | ||

| Feed Rate | Rapid feed | X/Y axis | mm/min | 6000 | 6000 | 6000 |

| Z1 axis | mm/min | 3000 | 3000 | 3000 | ||

| Quill Feed (Z2) | mm/min | X | 1-1500 | 1-1500 | ||

* Electric power capacity:100KVA

繁體中文

繁體中文 English

English