Horizontal Boring Milling Machine

CBA-110R2/CBA-110R3

CBA-135R2/CBA-135R3

CBA-135TR2/CBA-135TR3/CBA-135TR4

High Productivity

![]() The AC digital wrap around spindle drive and motor are more accurate and responsive than traditional analog spindle drives and motors.

The AC digital wrap around spindle drive and motor are more accurate and responsive than traditional analog spindle drives and motors.

![]() The spindle performance is continuously monitored to provide the most efficient cutting conditions. Each axis is independently controlled to provide maximum feed as required.

The spindle performance is continuously monitored to provide the most efficient cutting conditions. Each axis is independently controlled to provide maximum feed as required.

Powerful Spindle

![]() The specially designed spindle outer ring cooling system maintains constant bearing accuracy under normal operating conditions.

The specially designed spindle outer ring cooling system maintains constant bearing accuracy under normal operating conditions.

![]() This gear type auto-shift design and grease lubrication system also provides superior machine performance and reliability.

This gear type auto-shift design and grease lubrication system also provides superior machine performance and reliability.

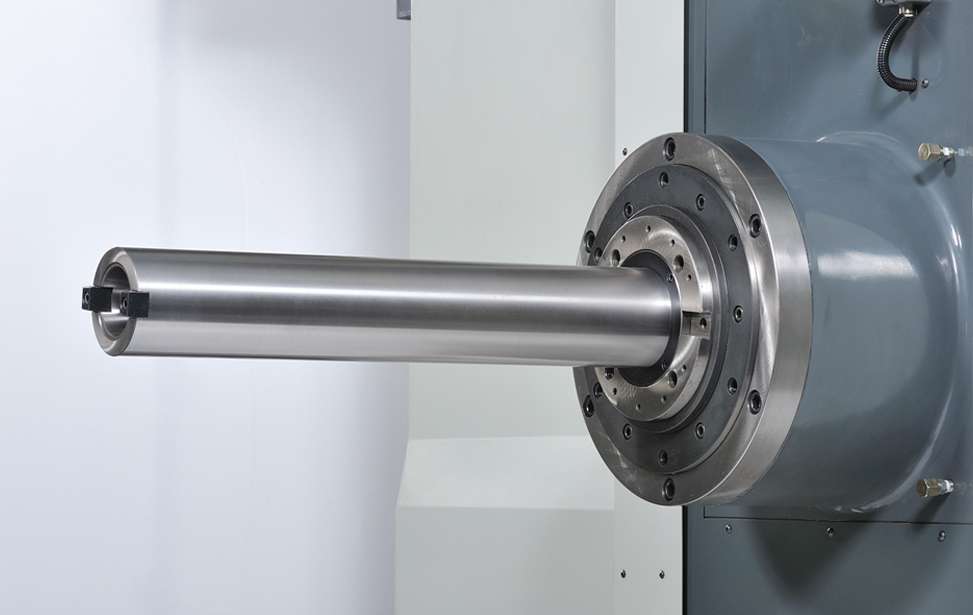

![]() The spindle and boring bar are made of SACM645 alloy. The spindle has been Nitrided to HRC62~68. This hardness maintains spindle form and insures high reliability. This increased rigidity increases the overall machine capability.

The spindle and boring bar are made of SACM645 alloy. The spindle has been Nitrided to HRC62~68. This hardness maintains spindle form and insures high reliability. This increased rigidity increases the overall machine capability.

![]() We use the very highest quality spindle bearings from SKF and NSK. These high quality bearings insure machine consistency and a longer machine life.

We use the very highest quality spindle bearings from SKF and NSK. These high quality bearings insure machine consistency and a longer machine life.

CBA Series Box Ways

![]() These highly rigid box way structures give you the very best machine durability. The material is high-frequency-heat-treat for stress relief.

These highly rigid box way structures give you the very best machine durability. The material is high-frequency-heat-treat for stress relief.

![]() The 4-in-1 design for CBA-110R and CBA-110R2 bed slide ways enhance the cutting capabilities in the Z-axis.

The 4-in-1 design for CBA-110R and CBA-110R2 bed slide ways enhance the cutting capabilities in the Z-axis.

Ease of Operation

![]() Fanuc, Siemens, and Heidenhain control panels are available options. These value added features will enhance your working capability, efficiency, and much more.

Fanuc, Siemens, and Heidenhain control panels are available options. These value added features will enhance your working capability, efficiency, and much more.

![]() We are sure that you will be very satisfied with the high level of quality and improved machine performance.

We are sure that you will be very satisfied with the high level of quality and improved machine performance.

High Precision Slide Ways

![]() Our auto grease lubricating system provides several advantages for the overall machine capability.

Our auto grease lubricating system provides several advantages for the overall machine capability.

![]() It not only maintains high accuracy during the long working hours, but also functions perfectly with low speed machining. The high precision ball screw axis transmission provides superior machine stability resulting in highly accurate work pieces.

It not only maintains high accuracy during the long working hours, but also functions perfectly with low speed machining. The high precision ball screw axis transmission provides superior machine stability resulting in highly accurate work pieces.

![]() The CBA-110R3 provides 2 additional linear slide ways to enhance durability and eliminate unwanted deflection. This significantly improves machine cutting accuracy

The CBA-110R3 provides 2 additional linear slide ways to enhance durability and eliminate unwanted deflection. This significantly improves machine cutting accuracy

Rotary Table

![]() This special combination of highly rigid box ways, ball screws, and worm gear automatic lubrication system provides a highly satisfying compact rotary table design. With the Heidenhain angle encoder installed in the rotary table center shaft, combined with our specially designed hydraulic clamping system and positioning index pins, our machines can achieve any cutting angle. Reinforced heavy cutting angles at 0°, 90°, 180°, and 270° are included features. Hence resulting in superior accuracy and cutting efficiency.

This special combination of highly rigid box ways, ball screws, and worm gear automatic lubrication system provides a highly satisfying compact rotary table design. With the Heidenhain angle encoder installed in the rotary table center shaft, combined with our specially designed hydraulic clamping system and positioning index pins, our machines can achieve any cutting angle. Reinforced heavy cutting angles at 0°, 90°, 180°, and 270° are included features. Hence resulting in superior accuracy and cutting efficiency.

| Model | Unit | CBA-110R2 | CBA-110R3 | ||

| Spindle | Main Motor(30min/cont.) | kw | 22/26 | ||

| Spindle Speed (Max.) | rpm | 2500 | |||

| Spindle Taper | ISO 50 / BT-50 | ||||

| Spindle Diameter | mm | Ø 110 | |||

| Max. Spindle Torque | Nm | 1025 | |||

| Travel | Work Table Travel X axis(Horizontal) | mm | 2000 | 3000 | |

| Spindle Travel Y axis(Vertical) | mm | 2000 | 2000 | ||

| Work Table Travel Z axis(Vertical) | mm | 1300 | 1500 | ||

| Spindle Travel W axis | mm | 600 | |||

| Distance from spindle nose to table center | mm | 780~2080 | 800~2300 | ||

| Distance from spindle center to table surface | mm | -35~1965 | -35~1965 | ||

| Rotary Table | Table Dimension | mm | 1400x1600 | 1600x1800 | |

| T-Slot | mm x No. | 22x9 | 22x9 | ||

| Max. Loading Weight | kg | 8500 | 10000 | ||

| Index | degree | 0.001° | 0.001° | ||

| Max. Rotation Diameter | mm | 2126 | 2408 | ||

| Table Rotation Speed | rpm | 0.8 | 0.8 | ||

| Feed | Rapid Feed | XYZW axis | mm/min | XYZ axis=10000 / W axis=3000 | |

| Feed Rate | X/Y/Z axis | mm/min | 1-5000 | ||

| Feed Rate | W axis | mm/min | 1-3000 | ||

| Machine Dimension (L×W×H) | mm | 5400x8450x4800 | 6350x9000x4800 | ||

| Machine Weight | Kg | 25000 | 29000 | ||

| Controller | Fanuc / Siemens / Heidenhain | ||||

* Rotary table adopt Heidenhain encoder ( Accuracy ±10〞)

- Tools and Tool Box

- Foundation Screws and Bolts

- Spindle Oil Cooler

- Spindle Box vertical movement counter weight

- Work Lamp

- Electrical Cabinet Cooler

- X axis Dust Cover

- Y axis Dust Cover

- Z axis Dust Cover

- MPG (Manual Pause Generator)

- Automatic Lubrication System

- Screw Chip Conveyor

- Steel Belt Chip Conveyor (with cart)

- ATC (Automatic Tool Changer)

- Coolant Through Spindle

- Linear Scale

- Spindle Support

- Facing head

- Transformer

- Splash Guard For Rotary Table

- Splash Guard For Operator

- Work Piece Measuring Device

| Model | Unit | CBA-135R2 | CBA-135R3 | ||

| Spindle | Main Motor(30min/cont.) | kw | 37/45 | ||

| Spindle Speed (Max.) | rpm | 5-2000 | |||

| Spindle Taper | ISO 50 / BT-50 | ||||

| Spindle Diameter | mm | Ø 135 | |||

| Max. Spindle Torque | Nm | 2150 | |||

| Travel | Work Table Travel X axis(Horizontal) | mm | 2000 | 3000 | |

| Spindle Travel Y axis(Vertical) | mm | 2000 | 2000 | ||

| Work Table Travel Z axis(Vertical) | mm | 1300 | 1500 | ||

| Spindle Travel W axis | mm | 700 | |||

| Distance from spindle nose to table center | mm | 700~2000 | 800~2300 | ||

| Distance from spindle center to table surface | mm | 0~2000 | 0~2000 | ||

| Rotary Table | Table Dimension | mm | 1400x1600 | 1600x1800 | |

| T-Slot | mm x No. | 22x9 | 22x9 | ||

| Max. Loading Weight | kg | 8500 | 10000 | ||

| Index | degree | 0.001° | 0.001° | ||

| Max. Rotation Diameter | mm | 2126 | 2408 | ||

| Table Rotation Speed | rpm | 0.8 | 0.8 | ||

| Feed | Rapid Feed | XYZW axis | mm/min | XYZ axis=10000 / W axis=3000 | |

| Feed Rate | X/Y/Z axis | mm/min | 1-5000 | ||

| Feed Rate | W axis | mm/min | 1-3000 | ||

| Machine Dimension (L×W×H) | mm | 5400x8600x5400 | 6350x9150x5400 | ||

| Machine Weight | Kg | 38000 | 40500 | ||

| Controller | Fanuc / Siemens / Heidenhain | ||||

* Rotary table adopt Heidenhain encoder ( Accuracy ±10〞)

- Tools and Tool Box

- Foundation Screws and Bolts

- Spindle Oil Cooler

- Spindle Box vertical movement counter weight

- Work Lamp

- Electrical Cabinet Cooler

- X axis Dust Cover

- Y axis Dust Cover

- Z axis Dust Cover

- MPG (Manual Pause Generator)

- Automatic Lubrication System

- Screw Chip Conveyor

- Steel Belt Chip Conveyor (with cart)

- ATC (Automatic Tool Changer)

- Coolant Through Spindle

- Linear Scale

- Spindle Support

- Facing head

- Transformer

- Splash Guard For Rotary Table

- Splash Guard For Operator

- Work Piece Measuring Device

| Model | Unit | CBA-135TR2 | CBA-135TR3 | CBA-135TR4 | ||

| Spindle | Main Motor(30min/cont.) | kw | 37/45 | |||

| Spindle Speed(Max.) | rpm | 2000 | ||||

| Spindle Taper | ISO 50 / BT-50 | |||||

| Spindle Diameter | mm | Ø 135 | ||||

| Max. Spindle Torque | Nm | 2150 | ||||

| Travel | Work Table Travel X axis (Horizontal) | mm | 2000 | 3000 | 4000 | |

| Spindle Travel Y axis (Vertical) | mm | 1800 | 2300 | 2800 | ||

| Column Moving Travel Z axis | mm | 1100 | 1400 | 1700 | ||

| Spindle Travel W axis | 700 | 700 | 700 | |||

| Distance from spindle nose to table center | mm | 1045~2145 | 1045~2445 | 1045~2745 | ||

| Distance from spindle center to table surface | mm | 0~1800 | 0~2300 | 0~2800 | ||

| Rotary Table | Table Dimension | mm | 1400x1600 | 1600x1800 | 1800x2000 | |

| T-Slot | mm x No. | 22x9 | 22x9 | 22x9 | ||

| Max. Loading Weight | kg | 8500 | 10000 | 12000 | ||

| Index | degree | 0.001° | 0.001° | 0.001° | ||

| Max. Rotation Diameter | mm | 2126 | 2408 | 2691 | ||

| Table Rotation Speed | rpm | 0.8 | 0.8 | 0.8 | ||

| Feed | Rapid Feed | XYZW axis | mm/min | XY axis=8000 / W axis=3000 / Z axis=5000 | ||

| Feed Rate | X/Y/Z axis | mm/min | 1-5000 | |||

| Quill Feed Rate | W axis | mm/min | 1-3000 | |||

| Machine Dimension (LxWxH) | mm | 7450x7610x5260 | 8300x7700x5760 | 9550x8100x6260 | ||

| Machine Weight | Kg | 39500 | 43000 | 46000 | ||

| Controller | Fanuc / Siemens / Heidenhain | |||||

* Rotary table adopt Heidenhain encoder ( Accuracy ±10〞)

- Tools and Tool Box

- Foundation Screws and Bolts

- Spindle Oil Cooler

- Spindle Box vertical movement counter weight

- Work Lamp

- Electrical Cabinet Cooler

- X axis Dust Cover

- Y axis Dust Cover

- MPG (Manual Pause Generator)

- Automatic Lubrication System

- Screw Chip Conveyor

- Steel Belt Chip Conveyor (with cart)

- ATC (Automatic Tool Changer)

- Work Table

- Coolant Through Spindle

- Linear Scale

- Spindle Support

- Facing head

- Angular Milling Head

- Universal Milling Head

- Transformer

- Splash Guard

- Splash Guard For Operator

- Work Piece Measuring Device

繁體中文

繁體中文 English

English