Horizontal Boring Milling Machine

CBA-200Q/CBA-110B

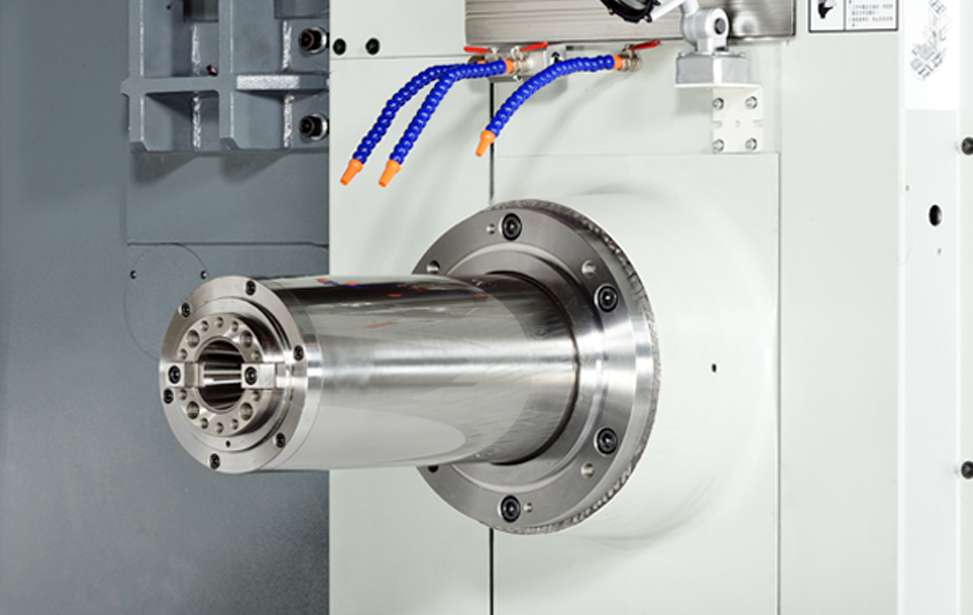

Quill diameter 200mm

![]() Keeping cutting ability when quill extend to 400mm.

Keeping cutting ability when quill extend to 400mm.

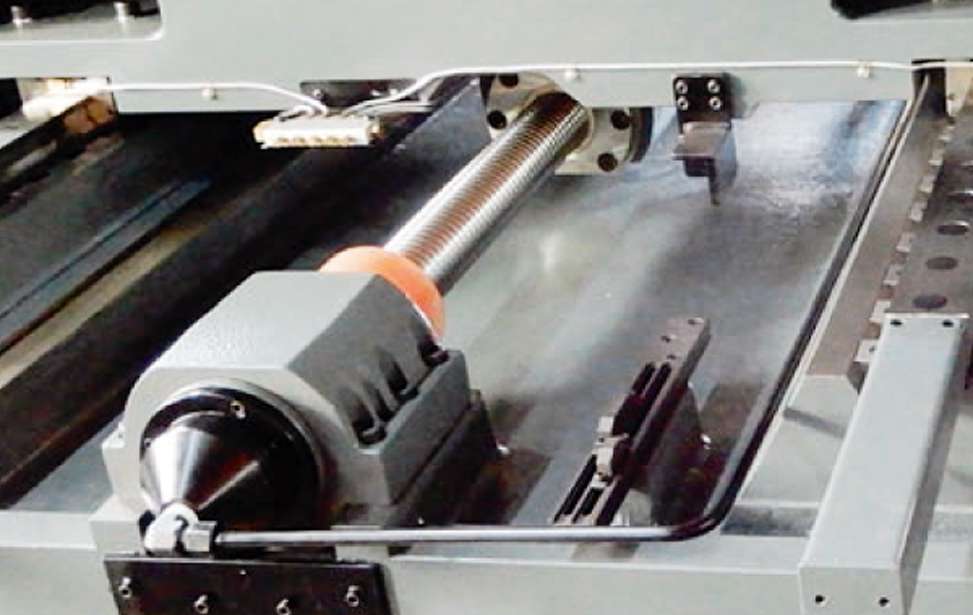

![]() Each axis is independently controlled to provide maximum feed as required.

Each axis is independently controlled to provide maximum feed as required.

High Power Spindlee

![]() Cooling system in spindle outer ring, it will remain bearings accuracy & heat raising in normal level.

Cooling system in spindle outer ring, it will remain bearings accuracy & heat raising in normal level.

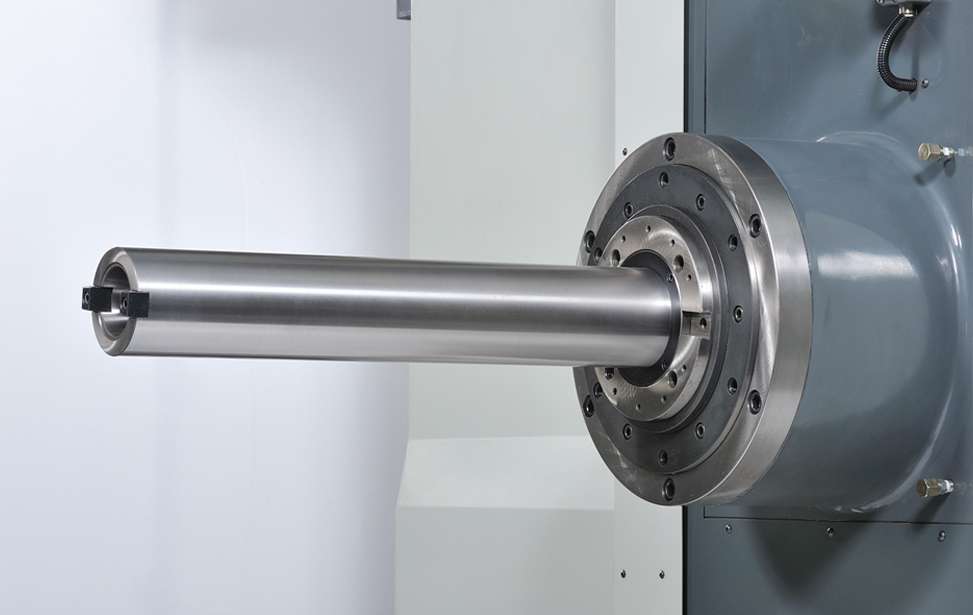

![]() Spindle is geared equipped High/Low speed & automatically changed. Adopted forcedlubricated system can assure lubrication stable.

Spindle is geared equipped High/Low speed & automatically changed. Adopted forcedlubricated system can assure lubrication stable.

![]() Spindle & quill are using special alloy steel material and have been heated treatment.

Spindle & quill are using special alloy steel material and have been heated treatment.

![]() Bearing adopted famous brands SKF, NSK and pass running & heat raising testing. Assure perfect accuracy & using life.

Bearing adopted famous brands SKF, NSK and pass running & heat raising testing. Assure perfect accuracy & using life.

Linear guideway : For Mold base industry

![]() X & Z axes : Linear guideway (standard), Y axis : Box way (standard).

X & Z axes : Linear guideway (standard), Y axis : Box way (standard).

![]() X&Z axes use linear guideway, low friction, good mechanical performance, fast running speed and easy maintenance.

X&Z axes use linear guideway, low friction, good mechanical performance, fast running speed and easy maintenance.

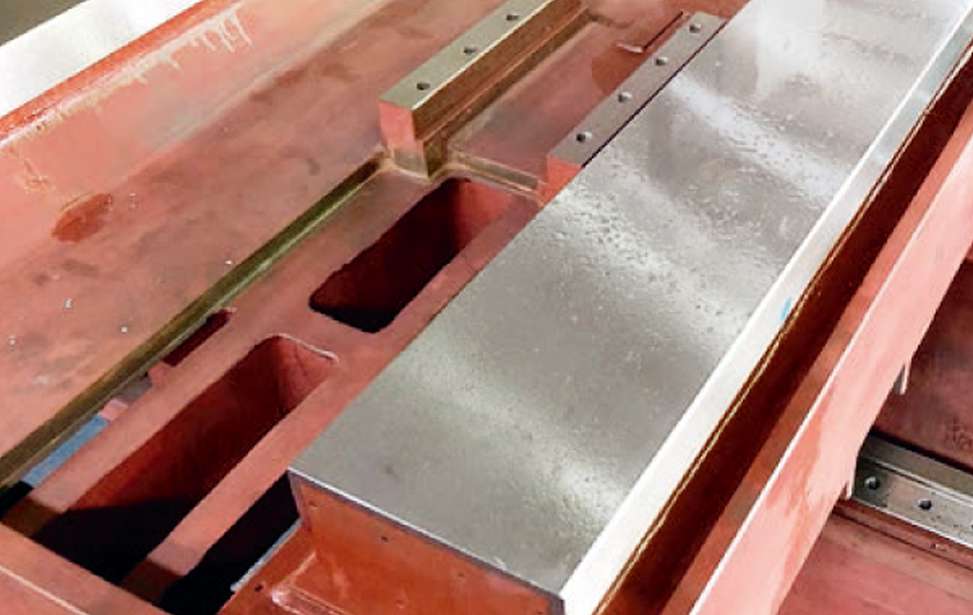

![]() Y axis uses box way, high rigidity rib structure and have been stress relief the heat treatment hardness is HRC43°~47°. Good at loading 200Q spindle weight and vertical movement steady.

Y axis uses box way, high rigidity rib structure and have been stress relief the heat treatment hardness is HRC43°~47°. Good at loading 200Q spindle weight and vertical movement steady.

Box way : For Machining industry

![]() X & Z axes box way (optional), Y axis box way (standard)

X & Z axes box way (optional), Y axis box way (standard)

![]() XYZ axes use box slide way, high rigidity rib structure and have been stress relief the heat treatment hardness is HRC43°~47°. The box way contact surface is large, the rigidity is good, the vibration resistance is strong, and good loading capacity performance suitable for heavy cutting.

XYZ axes use box slide way, high rigidity rib structure and have been stress relief the heat treatment hardness is HRC43°~47°. The box way contact surface is large, the rigidity is good, the vibration resistance is strong, and good loading capacity performance suitable for heavy cutting.

![]() The mating surfaces of the moving units are coated with a special fluorine resin, and scrapping so that the system for slide ways offers minimum friction resulting in high precision which will be maintained over a long period of time, this ensures a very smooth feed stroke even at low speeds without stick/slip.

The mating surfaces of the moving units are coated with a special fluorine resin, and scrapping so that the system for slide ways offers minimum friction resulting in high precision which will be maintained over a long period of time, this ensures a very smooth feed stroke even at low speeds without stick/slip.

![]() XYZ axes use precision ball screw.

XYZ axes use precision ball screw.

Easy Operation

![]() The switches on the pendant control box have the most efficient layouts for working respectively. This ensures improved operating efficiency.

The switches on the pendant control box have the most efficient layouts for working respectively. This ensures improved operating efficiency.

![]() The contents of programs and the current positions are displayed on the LCD display. This enables to make preparation and checking of the programs easily.

The contents of programs and the current positions are displayed on the LCD display. This enables to make preparation and checking of the programs easily.

![]() Using the portable operation control box allows the work to be adjusted to be centered, and permits manual cutting operation.

Using the portable operation control box allows the work to be adjusted to be centered, and permits manual cutting operation.

![]() Control system can choose international famous brands FANUC, SIEMENS, HEIDENHAIN. All CE NORM certificated in safety operation.

Control system can choose international famous brands FANUC, SIEMENS, HEIDENHAIN. All CE NORM certificated in safety operation.

Rotary working table

![]() The bed slideway is box way, adopted roller bearing and worm-gear equipped force lubricated system. Table center equipped Heidenhain rotary encoder assure index accuracy. Table equipped Hydraulic clamping system & positioning pin, assure indexing angle 0°, 90°, 180°, 270° heavy cutting accuracy.

The bed slideway is box way, adopted roller bearing and worm-gear equipped force lubricated system. Table center equipped Heidenhain rotary encoder assure index accuracy. Table equipped Hydraulic clamping system & positioning pin, assure indexing angle 0°, 90°, 180°, 270° heavy cutting accuracy.

| Model | Unit | CBA-200Q | ||

| Spindle | Spindle Motor(30min/cont.) | kw | 22 / 26 | |

| Spindle Speed(Max.) | rpm | Standard : L - 2000rpm Optional : H - 3000rpm |

||

| Spindle Taper | ISO 50 / BT-50 | |||

| Extended Quill Diameter | mm | 200 | ||

| Max. Spindle Torque | Nm | Standard : L – 1360Nm / 155 rpm Optional : H – 665Nm / 316 rpm |

||

| Travel | Work Table Travel X axis(Horizontal) | mm | 1500 | |

| Spindle Travel Y axis(Vertical) | mm | 1200 | ||

| Work Table Travel Z axis(Vertical) | mm | 1000 | ||

| Quill extension travel W axis | mm | 400 | ||

| Distance from spindle nose to table center | mm | 530 - 1530 | ||

| Distance from spindle center to table surface | mm | 0-1200 | ||

| - | Slideway | Standard : X & Z axis linear guide way | ||

| Optional : X & Z axis box way | ||||

| Y axis : Box way | ||||

| Rotary working table (B axis) | Table Dimension | mm | 1250×1250 | |

| T-Slot | mm x No. | 22×7 | ||

| Max. Loading Weight | kg | 4,500 | ||

| Index | degree | 0.001˚ | ||

| Max. Rotation Dia. | mm | 1768 | ||

| Rapid Rotation of Table | rpm | 4 | ||

| Feed | Rapid | XYZW axis | mm/min | X & Z axis linear guide way : 13000 |

| X & Z axis box way : 10000 | ||||

| Y axis : 10000 W axis : 3000 | ||||

| Feed Rate | X/Y/Z axis | mm/min | 1-5000 | |

| W axis | mm/min | 1-3000 | ||

| Machine Dimension(L×W×H) | mm | 7355×4500×3610 | ||

| Machine Weight | Kg | 17500 | ||

| Controller | Fanuc / Siemens / Heidenhain | |||

- Tool and Tool Box

- Foundation Screw and Bolt

- Spindle Oil Cooler

- Spindle Counter Weight Device

- Working Lamp

- Electro Cabinet Cooler

- X Axis Dust Cover

- Y Axis Dust Cover

- Z Axis Dust Cover

- MPG

- Auto Lubrication System

- Screw Chip Conveyor

- Steel Belt Chip Conveyor with Cart

- Automatic Tool Changer

- Coolant Through Spindle

- Liner Scale

- Transformer

- Splash Guard For Rotary Table

- Splash Guard For Operator

- Workpiece Measuring Device

- Working Table

| Model | Unit | CBA-110B | ||

| Spindle | Spindle Motor(30min/cont.) | kw | 22 / 26 | |

| Spindle Speed(Max.) | rpm | Standard : L - 2000rpm Optional : H - 3000rpm |

||

| Spindle Taper | ISO 50 / BT-50 | |||

| Extended Quill Diameter | mm | 110 | ||

| Max. Spindle Torque | Nm | 912Nm / 230 rpm | ||

| Travel | Work Table Travel X axis(Horizontal) | mm | 1500 | |

| Spindle Travel Y axis(Vertical) | mm | 1100 | ||

| Work Table Travel Z axis(Vertical) | mm | 1000 | ||

| Quill extension travel W axis | mm | 400 | ||

| Distance from spindle nose to table center | mm | 505 – 1505 | ||

| Distance from spindle center to table surface | mm | 0 - 1100 | ||

| - | Slideway | Standard : X & Z axis linear guide way | ||

| Optional : X & Z axis box way | ||||

| Y axis : Box way | ||||

| Rotary working table (B axis) | Table Dimension | mm | 1250×1250 | |

| T-Slot | mm x No. | 22×7 | ||

| Max. Loading Weight | kg | 4,500 | ||

| Index | degree | 0.001˚ | ||

| Max. Rotation Dia. | mm | 1768 | ||

| Rapid Rotation of Table | rpm | 4 | ||

| Feed | Rapid | XYZW axis | mm/min | X & Z axis linear guide way : 13000 |

| X & Z axis box way : 10000 | ||||

| Y axis : 10000 W axis : 3000 | ||||

| Feed Rate | X/Y/Z axis | mm/min | 1-5000 | |

| W axis | mm/min | 1-3000 | ||

| Machine Dimension(L×W×H) | mm | 7355×4500×3800 | ||

| Machine Weight | Kg | 18500 | ||

| Controller | Fanuc / Siemens / Heidenhain | |||

- Tool and Tool Box

- Foundation Screw and Bolt

- Spindle Oil Cooler

- Spindle Counter Weight Device

- Working Lamp

- Electro Cabinet Cooler

- X Axis Dust Cover

- Y Axis Dust Cover

- Z Axis Dust Cover

- MPG

- Auto Lubrication System

- Screw Chip Conveyor

- Steel Belt Chip Conveyor with Cart

- Automatic Tool Changer

- Coolant Through Spindle

- Liner Scale

- Transformer

- Splash Guard For Rotary Table

- Splash Guard For Operator

- Workpiece Measuring Device

- Working Table

繁體中文

繁體中文 English

English