Feature

Twin Head Milling Machine

- Fully automatic operation

- 4 sides cutting setting

- Ideal for middle and big square molds

- High efficiency

CBDM-600 / CBDM-800

| Specification |

Unit | CBDM-600 | CBDM-800 |

| Capacity | |||

| Table travel (X axis) | mm | 1030 | 1300 |

| Spindle head (Y、Z axis) | mm | 290 |

|

| Distance from spindle center to table surface | mm |

|

|

| Distance from spindle nose to table center | mm | 120 ~ 410 |

|

| Distance between spindles | mm | 240 ~ 820 |

|

| Workpiece size (L×W) | mm | □150 - □600 | □250 - □800 |

| Effective diameter of face cutter | mm |

|

|

| Workpiece size (H) | mm |

|

|

| Table | |||

| Working table size (L×W) | mm | 1600 x 520 | 1900 x 520 |

| The size of rotary working table (L×W×H) | mm | □500 x 260 x 90° | □500 x 260 x 90° |

| Rotary working table loading | kg | 850 | 2000 |

| Spindle | |||

| Spindle taper | BT-50 |

| |

| Spindle speed | r.p.m. | 70 ~ 1000 |

|

| Spindle change | stepless | stepless | |

| Spindle motor | kw | AC servo 7.5 kw |

|

| Spindle of feed | |||

| Cutting feed | mm/min | 10 ~ 3000 | 10~3000 |

| Rapid feed (X axis) | mm/min | 6000 | 6000 |

| Rapid feed (Y、Z axis) | mm/min | 5000 | 5000 |

| Machine weight | kg | 13500 | 15650 |

| Required floor space(L×W×H) | mm | 4350 x 4100 x 2550 | 4750 x 4600 x 2650 |

| Control system | Fanuc Touch panel controller | Fanuc Touch panel controller |

| Standard Accessories |

Optional Accessories |

| Foundation screws & pads |

Face cutter |

| Tools and tool box | Tips |

| Hydraulic rotary working table | Transformer |

| Hydraulic system | |

| Hydraulic clamping device | |

| X axis dust cover | |

| Y、Z axis dust cover | |

| Screw type chip conveyor | |

| Half splash guard | |

| Working light & Warning light | |

| Air conditioner of electric cabinet | |

| Air blow device | |

| Datum plane stopper | |

| Workpiece auto measure device | |

| Fanuc 0i-MF touch panel |

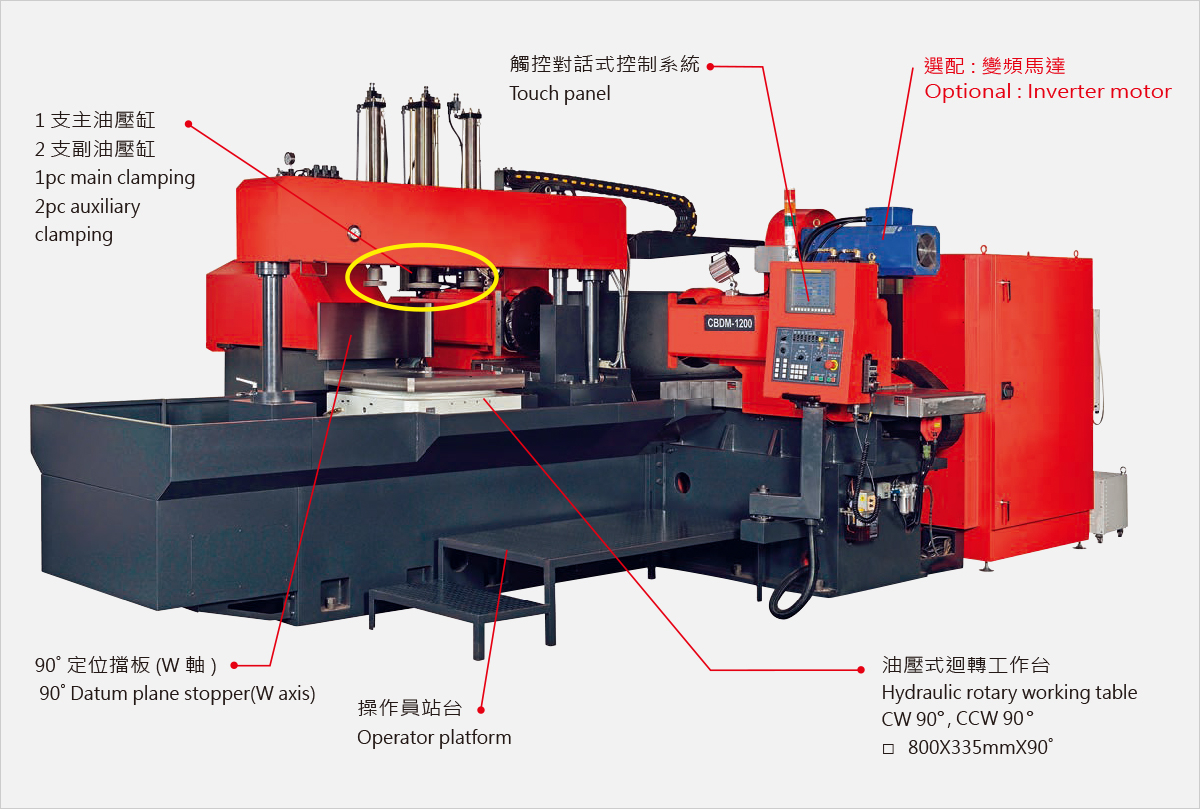

CBDM-1000 / CBDM-1200

| Specification |

Unit | CBDM-1000 | CBDM-1200 |

| Capacity | |||

| Table travel (X axis) | mm | 1500 | 1700 |

| Spindle head (Y、Z axis) | mm |

| 430 |

| Distance from spindle center to table surface | mm |

| 575 |

| Distance from spindle nose to table center | mm |

| 295 ~ 725 |

| Distance between spindles | mm |

| 590 ~ 1450 |

| Workpiece size (L×W) | mm | □350 - □1000 |

|

| Effective diameter of face cutter | mm |

|

|

| Workpiece size (H) | mm |

|

|

| Table | |||

| Working table size (L×W) | mm | 2200 x 520 | 2500 x 700 |

| The size of rotary working table (L×W×H) | mm | □600 x 285 x 90° | □800 x 335 x 90° |

| Rotary working table loading | kg | 3200 | 4500 |

| Spindle | |||

| Spindle taper |

| BT-60 | |

| Spindle speed | r.p.m. |

| 70 ~ 450 |

| Spindle change | stepless | stepless | |

| Spindle motor | kw |

| Inverter motor 22.5 kw |

| Spindle of feed | |||

| Cutting feed | mm/min | 10 ~ 3000 | 10 ~ 3000 |

| Rapid feed (X axis) | mm/min | 6000 | 6000 |

| Rapid feed (Y、Z axis) | mm/min | 5000 | 5000 |

| Machine weight | kg | 16500 | 19000 |

| Required floor space(L×W×H) | mm | 5000 x 4600 x 2650 | 5500 x 4700 x 2650 |

| Control system | Fanuc Touch panel controller | Fanuc Touch panel controller |

| Standard Accessories |

Optional Accessories |

| Foundation screws & pads |

Face cutter |

| Tools and tool box | Tips |

| Hydraulic rotary working table | Transformer |

| Hydraulic system | |

| Hydraulic clamping device | |

| X axis dust cover | |

| Y、Z axis dust cover | |

| Screw type chip conveyor | |

| Half splash guard | |

| Working light & Warning light | |

| Air conditioner of electric cabinet | |

| Air blow device | |

| Datum plane stopper | |

| Workpiece auto measure device | |

| Fanuc 0i-MF touch panel |

Video

Twin Head Milling Machine

CBDM-800 ( Touch panel )